Solar energy belongs to renewable energy, which is clean, pollution-free, large reserves, renewable and so on. It is one of the available new energy known to mankind at present. The report of the 19th National Congress of the Communist Party of China proposed to promote energy transformation, reduce coal consumption and unswervingly promote clean development. In 2018, according to the prediction of relevant authorities, the new installed capacity of photovoltaic in the world is about 106GW, and the new installed capacity in China is about 40GW.

Lightning protection is an indispensable part of the entire photovoltaic power station, which is related to the safe and normal operation of the power station and the safety of power station personnel. As the main choice of new energy in the future, there is no detailed design specification in China to define how to conduct lightning protection design of photovoltaic power plants. Therefore, this paper mainly summarizes and summarizes lightning protection methods of photovoltaic power plants in combination with work experience and relevant specifications, and states personal views.

1. Composition of grid connected photovoltaic system and main lightning protection facilities

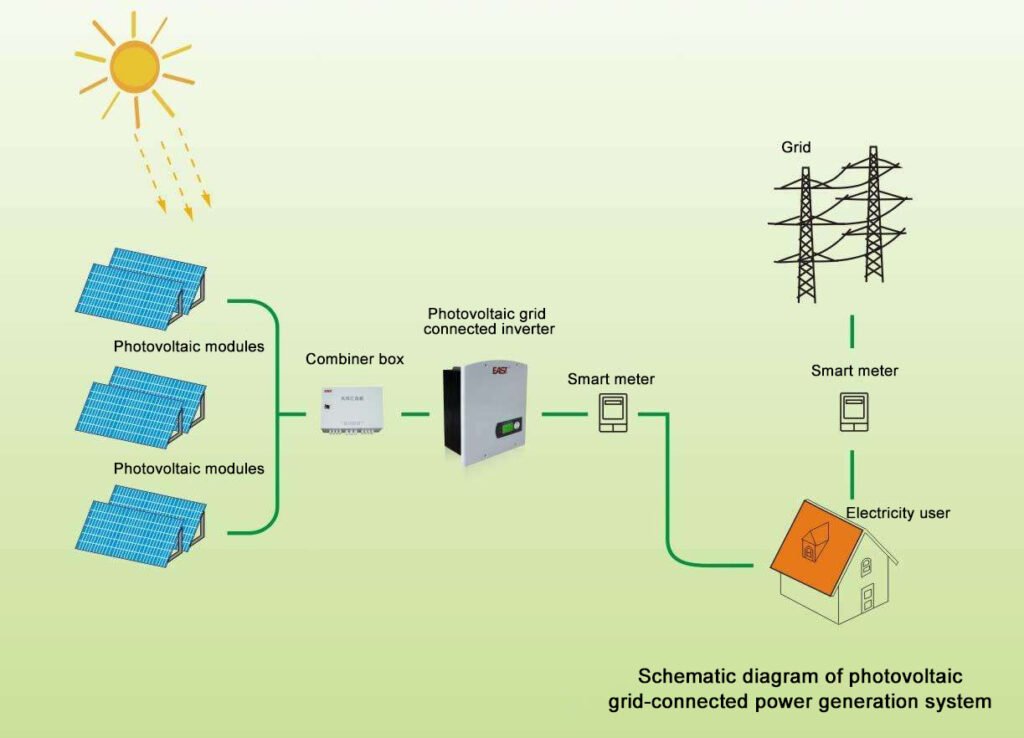

PV power generation systems are mainly divided into three categories: independent, distributed and grid connected PV power generation systems. This paper mainly discusses the grid connected power generation system. The working principle of grid connected photovoltaic power generation system is that the ground photovoltaic array converts solar energy into DC power, which is sent to the DC power distribution cabinet after converging through the combiner box, and then transmitted to the grid connected inverter. After the inverter converts DC power into AC power, it is transmitted to the AC power distribution cabinet, and then sent to the power grid after boosting.

The grid connected photovoltaic power station is mainly composed of photovoltaic array, combiner box, DC transmission cable, DC distribution cabinet, grid connected inverter, AC distribution cabinet, step-up transformer, transmission line, metering, control, communication and other equipment. The battery pack, battery controller and solar tracking control system are not considered in this paper.

The hazards of lightning on grid connected photovoltaic power plants are mainly divided into three types, namely direct lightning, lightning surge intrusion and lightning electromagnetic pulse in equipment room.

Direct lightning stroke: when lightning strikes the ground photovoltaic array, equipment room or transmission line and passes through the electric shock generated by its discharge to the ground, due to the high temperature thermal effect of lightning current, on the channel where the lightning current flows, the object moisture is heated and vaporized and expands violently, generating a strong impact mechanical force, which can break human tissues, building structures, equipment parts, etc., leading to casualties and building damage, And equipment damage.

Lightning surge invasion: when lightning strikes on the output line, DC cable line or metal pipe, the lightning current invades the room along the cable line or metal pipe, or when lightning strikes near the cable line or metal pipe, strong alternating magnetic field is generated due to the large gradient of lightning current change, which makes the metal conductor near the lightning strike point produce induced current, and the induced current invades the equipment room along the metal pipeline, Damage to equipment or endanger personal safety.

Lightning electromagnetic pulse in equipment room: when lightning strikes buildings or nearby, the lightning current enters the building’s direct lightning protection system and produces a fast changing electromagnetic field, which will affect all electronic equipment around. The change of electric field caused by the change of magnetic field may lead to the failure of electronic and electrical equipment of communication, monitoring and other systems in the computer room.

To sum up, the components of grid connected photovoltaic power stations that need to take lightning protection measures include: ground photovoltaic array, DC transmission lines, metal pipelines, outgoing lines, building machine rooms and equipment cabinets (including DC distribution cabinet, grid connected inverter, AC distribution cabinet, step-up transformer, metering, control, communication equipment, etc.).

2. Lightning protection scheme for grid connected photovoltaic power station

2.1 Determination of lightning protection category

Photovoltaic array of photovoltaic power station belongs to open space, which is generally distributed in open space, and its area is large, so the probability of direct lightning stroke will increase correspondingly. The lightning protection category refers to the judgment of Class III lightning protection buildings in the Code for Design of Lightning Protection of Buildings for the open-air storage yard with a large number of grain, cotton and inflammables. Although the photovoltaic array does not belong to inflammables, the investment is huge. If personnel injury or equipment damage is caused by lightning, the loss is also huge. Although the PV array has a low fire risk, it is necessary to conduct lightning protection design for the PV array from the perspective of reducing economic losses. Considering all factors, it is recommended to consider the lightning protection buildings as Class III.

2.2 Direct lightning protection

Direct lightning protection is mainly divided into three parts, equipment room, ground photovoltaic array and outgoing line.

1) Protection measures against direct lightning strike in equipment room

The direct lightning protection of equipment room shall be designed according to Class III lightning protection buildings φ 12mm galvanized round steel is used as the lightning arrester, which is laid at the corners, eaves, eaves corners and other places vulnerable to lightning, and the composition of the whole roof is not more than 20m × 20 m air termination network. Use 2 pieces in the concrete column of the building φ The main reinforcement ≥ 16mm is used as the downlead, and its spacing is not more than 25m. The upper end of the downlead is connected with the lightning strip, and the lower end is connected with the foundation grounding grid.

2) Direct lightning protection measures for ground photovoltaic array

The PV module of PV array can use its metal frame as the lightning arrester and metal support as the grounding wire. The artificial grounding grid consisting of vertical grounding electrode and horizontal grounding electrode shall be used in the station, and ± 50mm × 50mm × As the vertical grounding electrode, the 5mm angle steel shall be buried in the soil at a depth of not less than 0.5m, and 40mm shall be used × 4mm flat steel is used as horizontal grounding electrode, which is buried in trenches. The spacing of vertical grounding electrodes shall be more than twice of the buried depth and uniformly arranged. For PV modules fixed on the same metal frame, the metal frame grounding points shall be more than 2, and the spacing of each grounding point shall not be more than 25m. The lightning protection grounding of photovoltaic array shall share the same grounding device with its protective grounding, system grounding and the grounding system of equipment room; The grounding resistance of the shared grounding device shall meet the minimum requirements of each grounding system, generally not more than 1 Ω.

3) Protection measures for direct lightning strike of outgoing line

The outgoing line shall be equipped with lightning conductor to reduce the harm caused by direct lightning strike.

2.3 Requirements for lightning surge prevention

The protection against lightning surge invasion is mainly aimed at the protection of incoming and outgoing metal pipelines, including DC input cables, metal pipelines, combiner boxes and outgoing lines.

1) Measures for preventing lightning surge invasion of DC transmission lines and metal pipes

In order to reduce lightning current or surge current entering the machine room through DC transmission cables, DC transmission cables shall be shielded cables with shielding layers. At least equipotential connection shall be made at the beginning, end, branch and junction of lightning protection area of metal pipes to prevent lightning current or surge current from entering the machine room through DC transmission line and damaging equipment cabinet.

2) Anti lightning surge invasion measures for combiner box

The DC surge protector shall be installed in the combiner box, that is, the output terminal of the combiner box shall be installed between the positive pole to ground, the negative pole to ground, and the positive pole to negative pole respectively. The main technical parameters of the DC surge protector shall meet the following requirements: the rated impact current Iimp ≥ 12.5kA (10/350 μ s)。 When the photovoltaic array in the station or the nearby ground is struck by lightning, the lightning current or surge current formed in the transmission line will discharge through the surge protector in the combiner box. In addition, according to the actual number of DC transmission lines, if it is necessary to further reduce the surge current, a surge protector with matching energy can be added in the multi-level combiner box to achieve the purpose.

It should be noted that the DC power surge protector installed at the combiner box should meet the requirements of the application characteristics of the photovoltaic system, and the maximum continuous working voltage should be greater than or equal to the maximum open circuit voltage of the photovoltaic module. The above measures should be taken comprehensively to reduce the lightning surge current as much as possible.

3) Anti lightning surge invasion measures for outgoing lines

The lightning surge prevention measures for outgoing lines are mainly to install zinc oxide arresters on the high-voltage side of the transformer, and use the good non-linear volt ampere characteristics of zinc oxide arresters to lead the surge current on the lines to the earth.

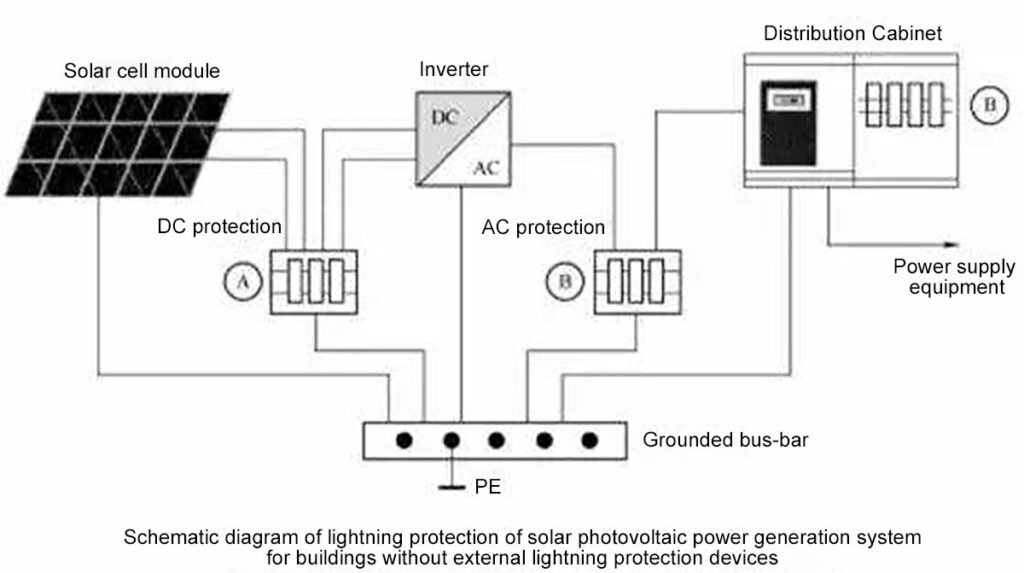

2.4 Lightning electromagnetic pulse protection measures

The protection of lightning electromagnetic pulse is mainly aimed at the equipment in the machine room, which is divided into shielding, equipotential and integrated wiring: equipotential connection ends shall be set at the entrance and exit of the line, and all incoming and outgoing metal pipes or line shielding layers in the machine room shall be equipotential connected at the junction of the lightning protection area. At the same time, the equipment cabinet, metal bridge, metal pipe, metal outer layer of shielded cable, equipment safety protection grounding, surge protector grounding terminal, etc. in the machine room shall be connected with the grounding reference point of S-type structure or the grid of M-type structure with the shortest path. The equipotential connection network of the machine room and the grounding body of the photovoltaic array shall maintain the same potential to prevent the counterattack caused by potential difference.

According to the working voltage requirements, the DC distribution cabinet shall be equipped with an appropriate DC surge protector. The input terminal of each DC circuit of the inverter can choose whether to install a surge protector according to the actual situation, so as to reduce the residual voltage generated by lightning current and make it less than the equipment withstand voltage. The low-voltage side of the step-up transformer shall be installed with a surge protector for Class I test (rated discharge impulse current Iimp ≥ 12.5kA), and the high-voltage side shall be installed with a zinc oxide arrester. In addition, when arranging the direction of signal cables in the machine room, the area of the inductive loop formed by the cables themselves should be minimized (Figure 1). The signal line surge protector shall be selected according to the working frequency, characteristic impedance, transmission medium, working voltage, interface form and other parameters of the line. The surge protector with small voltage insertion loss, small partial capacitance, and suitable for the longitudinal balance and near end crosstalk indicators shall be selected and set at the interface of the lightning protection area.

3. Ankeri APV lightning protection photovoltaic combiner box

In a large photovoltaic power generation system, a large number of photovoltaic cell modules need to be combined in series and parallel to reach the required voltage and current value, so as to maximize the power generation efficiency. The APV series intelligent photovoltaic combiner box can also provide the functions of photocell current measurement, monitoring the operation status of the solar panel in the photocell array, battery voltage, total power of the confluence, branch power, collection of the status of the combiner box lightning protector, collection of the status of the DC circuit breaker, relay contact output, and sensor interfaces such as wind speed, temperature, irradiator for customers to choose from. The device is equipped with RS485 interface as standard, The measured and collected power data and equipment status can be uploaded to the monitoring system.

Product features

♦ Comply with CGC/GF 037:2014 Technical Specification for PV Array Combiner Box;

♦ The protection grade is IP65, meeting the requirements for indoor and outdoor installation;

♦ Hall sensor is adopted for isolated measurement, with maximum 16 channels of input;

♦ PV special fuse is used, withstand voltage is DC1kV, and fuse current can be selected;

♦ Optional voltage measurement function, maximum measurement voltage DC 1kV;

♦ Optional external sensor input interface, which can monitor irradiation, temperature, wind speed, etc;

♦ It has RS485 communication interface and uses ModBus RTU communication protocol;

♦ A variety of power supply modes (DC24V, AC/DC220V, DC1000V. DC1500V) can be selected, which are applicable to household roof solar energy or professional photovoltaic power station applications;

♦ According to customer demand, PV DC circuit breakers, PV DC fuses, lightning protectors and other components from well-known domestic and foreign brands can be used.

Ankeri AGF-MxxT series perforated photovoltaic combiner collection device is specially applied to intelligent photovoltaic combiner box, which is used to monitor the operating status of the solar panel in the photovoltaic array, measure the string current, collect the status of the lightning arrester in the combiner box, collect the status of the DC circuit breaker, and upload the measured and collected data and equipment status with RS485 interface.

It is designed according to CNCA/CTS 0001-2011A Technical Specifications for Photovoltaic Convergence Equipment, and has the following characteristics:

1) The primary current is connected through perforation, with a maximum of 20A, which is convenient for installation and high in safety;

2) With 3-way switching value status monitoring, it can monitor the status of lightning arrester and circuit breaker in the combiner box;

3) With internal temperature measurement function, it can monitor the temperature in the box in real time to ensure electrical safety;

4) With the maximum DC 1500V bus voltage measurement function;

5) Local display/LCD display head is available for convenient debugging and maintenance;

6) With RS485 interface and Modbus RTU protocol, it can upload the monitoring data to the background system

4. Conclusion

Lightning is listed as one of the ten natural disasters. Although lightning stroke is a small probability event, the damage caused by lightning stroke is huge. Therefore, we should do a good job of lightning protection based on the concept of prevention first and combination of prevention and control, without taking chances. In the photovoltaic power station system, it is necessary to consider which path lightning will affect which facilities and equipment, so as to take effective measures to ensure safe and healthy operation.